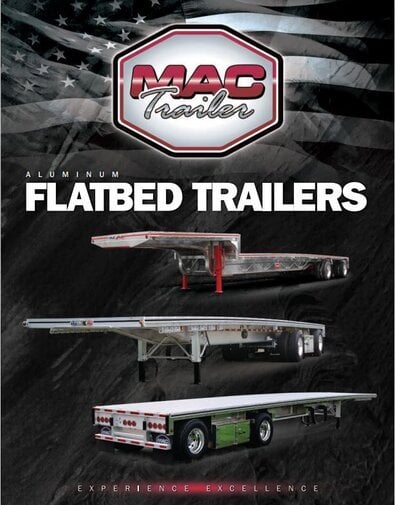

MAC Flatbed Trailers

Our flatbed trailers deliver on quality and dependability when you need it most.

Flatbed Trailer – Road Warrior™

Overview:

Turn to MAC Trailer for your platform trailers, when quality workmanship, dependability and longevity are critical for your business. Designed to haul loads that are evenly distributed as well as loads that are concentrated in weight.

Materials:

Aluminum

Load Capacity:

52K 4’ concentrated load, up to 80K 4’ concentrated load

FIND A DEALER

Turn to MAC Trailer for your platform trailers, when quality workmanship, dependability and longevity are critical for your business. Designed to haul loads that are evenly distributed as well as loads that are concentrated in weight.

Materials:

Aluminum

Load Capacity:

52K 4’ concentrated load, up to 80K 4’ concentrated load

Drop Deck Flatbed Trailer

Overview:

The ultimate drop deck flatbed trailer in the industry, MAC Trailer offers a high load capacity, while still being lightweight. The unique manufacturing process forms the all-aluminum neck prior to the final heat treatment of the metal, maintaining the strength and structural properties of the alloy.

Material:

Aluminum

Load Capacity:

52K concentrated load rating

FIND A DEALER

The ultimate drop deck flatbed trailer in the industry, MAC Trailer offers a high load capacity, while still being lightweight. The unique manufacturing process forms the all-aluminum neck prior to the final heat treatment of the metal, maintaining the strength and structural properties of the alloy.

Material:

Aluminum

Load Capacity:

52K concentrated load rating

MLP™ 8 Flatbed Trailer

Overview:

Increase your hauling capacity with an 8” low-profile neck. Great for hauling general building materials, pipe and palleted general freight loads.

Material:

Aluminum

Load Capacity:

45K concentrated/80K evenly distributed